The Coronavirus pandemic has already seen many examples of those in the entertainment technology and production industry putting their skills and resources to good use – from morale raising actions to physical contributions and manufacturing items to aid the massive efforts worldwide to contain the spread of infection.

In normal times, S-Group in France is a busy full production and rental operation with four regional bases and a HQ in Alès, north of Nimes in the South of France, and this time of year they’d have an average of 20 tours on the road as well as servicing numerous long term rentals …

However, with the live show and event Industry at a complete standstill … S-Group’s manufacturing division has instead energised its 3D printing capabilities assist in producing protective visors for workers engaged in the various frontline healthcare and first response services.

S-Group founder and owner Leon Van Empel explained that the schedule of the manufacturing facility – part of the HQ building – is usually led by the company’s internal engineering office as their workload includes the design and build of custom stage, set and scenery pieces and props plus other bespoke elements for shows and events.

They have CNC machinery, water / laser cutting, welding, assembly and electronics integration plus textile and plastic works at their disposal, plus the 3D Printing, which is used either directly for customer requirements or for internal development projects.

The protective mask / visor project all started when Leon was looking at the Facebook page of Visiere Solidaire, a citizen supported network for the manufacturer of protective visors for care givers and public officials.

The organisation was reaching out to companies with 3D printing facilities, asking if they could assist in making this vital kit which is badly needed by those working in close contact and proximity to people including those who have tested positive for the virus. “We were extremely keen to try and help the enormous efforts and sacrifices being made by those on the front line … and immediately offered the services of our 3D printing” explained Leon.

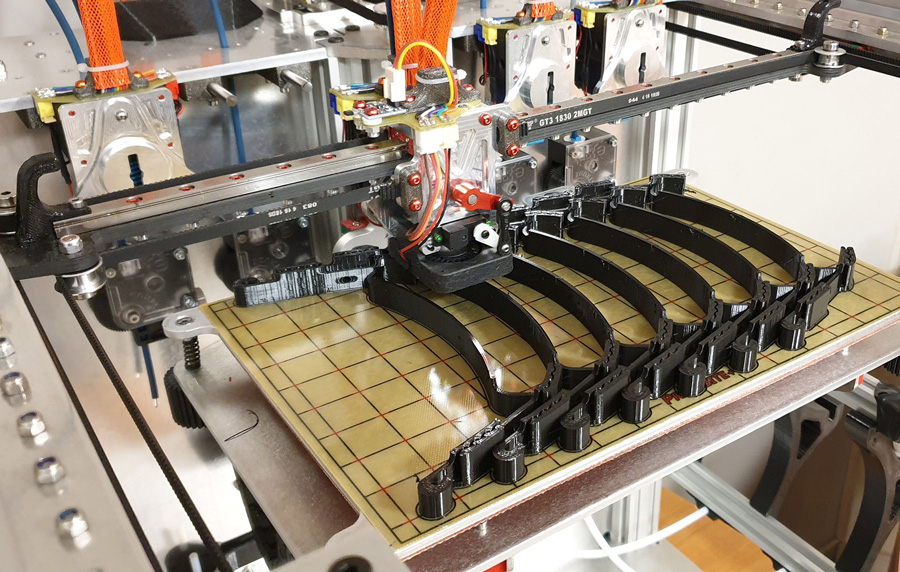

S-Group has a Fused Deposition Modelling printer which was bespoke designed and built for the company by IT manager, Thibaut Pral. He downloaded into the printer software one of the .stl files developed and made available free of charge by the designers of the Newshield group of the Newshield group.The printer uses PET-G filament for both good flexibility and an excellent resistance to decontaminating chemicals.

A local Facebook group allocates “orders” to those companies or individuals in the area who have offered the 3D printing manufacturing services. These companies supply their machines and the thermoplastic material required – in S-Group’s case to make the main part of the shield that attaches to the head – while other local suppliers – linked through the same page – produce the clear plastic sheets for the visor fronts.

When the visor fronts arrive at S-Group, They assemble the complete visors, working within the social distancing rules and wearing full protective PPE. The completed assembled masks, and a user manual explaining how to make a decontaminant utilizing diluted bleach are given a final clean with bleach solution before being collected, a task also managed via the Facebook page who then also arranges their distribution.

This is free to those who have requested the equipment. Primarily delivered to healthcare workers including freelance nurses, dental surgeons as well as shop employees and others involved in the food supply chain.

“We are extremely proud that our employees are prepared to do this and put our temporarily unused company resources to good use during the crisis producing this much-needed essential equipment.”

The shortage of essential PPE equipment has been a well-documented issue and is a common thread in many countries in the thick of battling Covid-19, which is straining healthcare services worldwide. France is one of the worst hit countries in mainland Europe, along with Italy and Spain.

Looking forward to the future, Leon is keeping positive and envisioning a time when “We can reunite our fantastic team and restart the premium services we offer to our customers” … which will also entail getting the 1000 plus Robe moving lights back on the road on a dynamic mix of productions and installations.