GL events has installed a technical grid in the 10,000 square-meter hall of the Grand Palais Ephémère, with 507 m of trussing and 54 radio-controlled chain hoists that are operated via a brand-new, intelligent remote control developed by Sonoss.

Built to replace the Grand Palais during its restoration, the Grand Palais Éphémère hosts art exhibitions, high-profile events and fashion shows in its 10,000-square-meter venue. It is equipped with a technical grid that consists of more than half a kilometer of trussing and 54 chain hoists controlled via a brand-new, intelligent remote control system developed by Sonoss!

Following a call for bids issued in September 2019 by the Réunion des musées nationaux – Grand Palais and Paris 2024, GL events was awarded the contract to design, build, operate and eventually dismantle the Grand Palais Éphémère.

When GL Events won the contract to develop the Grand Palais Éphémère, the company’s lighting/structure manager, Alexandre Trapon, was responsible for adapting the exhibition hall to the needs of the event industry, planning the motorized technical trusses, the routing of the networks used for production and the architectural and venue lighting. He carried out a precise and meticulous study during the Covid-19 epidemic to make this space as easy and quick as possible to work with.

We went to pay him a visit in this beautiful building that combines glass and wood under a PVC and ETFE covering, accompanied by Manuel Lauwerier and Philippe Coudyser from Sonoss, who developed the innovative chain hoist control for this impressive performance space.

SLU : The Grand Palais Éphémère is, as its name indicates, a temporary facility. How long will it last?

Alexandre Trapon, responsable technique lumière/structure de GL events : Since the renovation of the Grand Palais is scheduled to be completed in 2024, this building will be dismantled as soon as the 2024 Paralympic Games are over. The specifications were very stringent in terms of the materials to be used, their recyclability and acoustics, because we are in a densely residential area.

And in response to your observation, since the Champ de Mars is one of the most emblematic sites in Paris, we couldn’t set up a conventional temporary structure. So the structure of the building is mostly made of wood.

SLU : When did you start working on this project?

Alexandre Trapon : In September 2019, when GL events was awarded the contract, we sourced companies to construct the building, electricians and specialized contractors. When the specifications came to us, we adapted them to the needs of the event industry.

We’re specialized in building and equipping large temporary structures, generally marquees. GL Events also builds a lot of stadiums that are not temporary but can be upgraded. We come from the events sector, so everything seems simple to us.

SLU : Have exhibitions come back at the same pace as before Covid?

Alexandre Trapon : Given that the trade shows didn’t go on during Covid, the schedule for the Grand Palais Ephemera is very packed for 2022. The shows and events scheduled for the first half of 2021 were postponed to the end of the year, resulting in a particularly busy schedule between September and December 2021. In this context, we have made sure to put in place technologies that optimize the installation time of the audiovisual components.

The structure and the motors

507 square meters of Sixty82 M39S square trussing are installed in the exhibition hall and are moved by 54 Verlinde D8+ chain motors, all with NeoFeu load arrestors!

Alexandre provided a central grid of 23 meters on each side with a crossbeam, equipped with eight SL10 D8+ chain hoists (1 ton) with Neo Feu Big (1 ton) load arrestors, two 70 m trusses powered by 14 Verlinde SL5 D8+ chain hoists (500 kg) with 500 kg load arrestors, and six 42 m trusses lifted by 14 SL5 chain hoists with load arrestors.

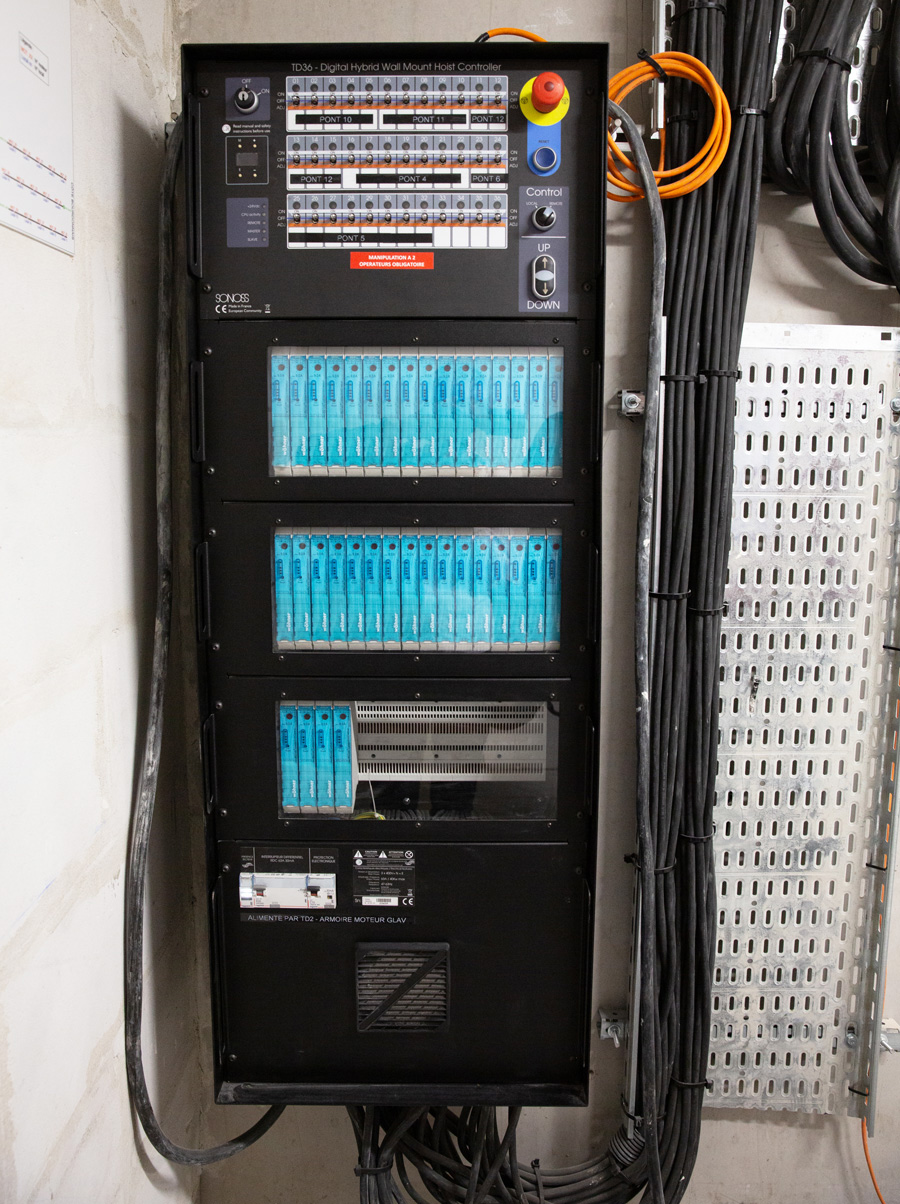

A brand-new Sonoss remote control, with hybrid motor starters and group memories, and which can be used in either wired or wireless mode, brings together all the hoist controls in a very compact format with a host of safety features.

Alexandre Trapon : To control the grid, truss by truss, we needed to procure a reliable, practical and safe system for controlling the chain hoists. I drafted a set of specifications and sent them to Philippe Coudyser, the head of Sonoss, because we already had some of their remote controls.

The system he suggested didn’t exist anywhere else and it wasn’t yet in the Sonoss catalog. I chose this solution, which was not yet functional at the time, but I knew it was coming. For me, it was the only one that ensured safety and a reduction in deployment time.

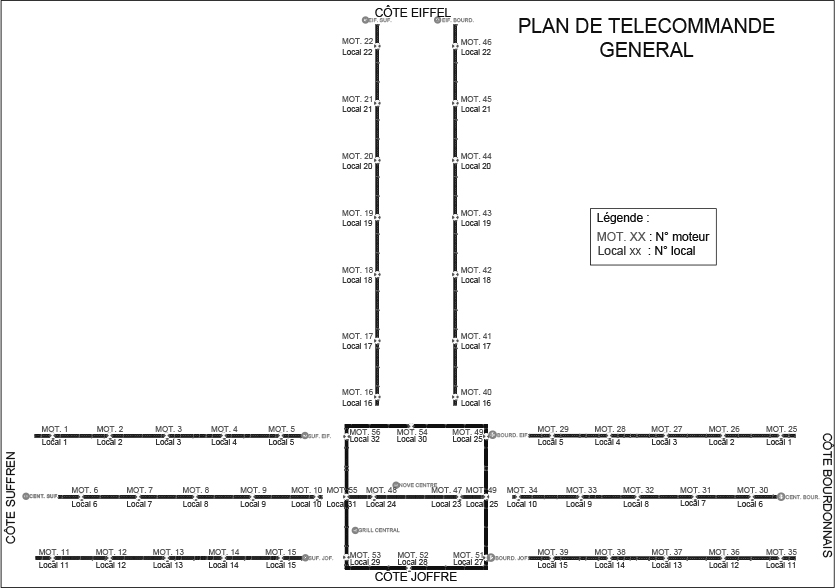

We have two remote control stations on the third floor, one at each end of the building. The control panel in the first room has 24 hybrid starters, and the one in the second station, located on the opposite side of the building, has 36 of the same technology.

Each switch is connected to a chain motor, and I can control them either manually or with the remote control which integrates the control of all the motors with two possibilities, wired or wireless. It’s really convenient when you’re downstairs in the exhibition hall to be able to operate the trusses remotely via radio.

In the product designation, 72 is the maximum number of controllable motors, 20 is the maximum number of groups, W stands for Wired and WL for Wireless (RF).

The system also makes it easy to program groups of hoists, one program per truss, and to operate them with a single switch.

And if one motor isn’t running at the same speed or is loaded a little more than the others, and you see a discrepancy, you can easily select it, adjust it, and put it back in the group.”

Here is a tutorial on the operation of the remote control, produced by Manuel Lauwerier.

SLU : What is the advantage of hybrid starters?

Manuel Lauwerier, directeur technique de Sonoss : The hybrid starter is a three-phase solid-state inverter switch. It is the semiconductors, triacs, which close the contact. They absorb the voltage and, after five milliseconds, the relay connected in parallel is automatically connected. It therefore doesn’t suffer from the electric arc of starting that wears out the contacts, and its life span is therefore easily ten times longer.

Safety

Hybrid starters are not only resistant to wear and tear. They also ensure safety.

Alexandre Trapon : The advantage of the hybrid starter is that it also limits the load. If it recognizes that a motor is unloaded or overloaded, it detects an error and shuts down the entire remote control system to avoid disaster.

Philippe Coudyser, Président de Sonoss : The motors are protected because each switch channel is adjustable from 1.5 A to 9 A according to the motor characteristics specified by the manufacturer. In the event of an under-load or overload, the switch detects an error and cuts off the power. It’s very different in terms of operation and safety from a normal remote control.

Manuel Lauwerier : Whatever the problem, overload, under-load, phase offset, an unconnected phase, power loss, a disconnected motor, the remote detects it and shuts down the system.

The error is displayed by a set of indicator LEDs. Each group of red or orange LEDs has a specific meaning, and if the hybrid starter module is defective, you simply remove it and replace it.

Alexandre Trapon : These are essential safeguards because the grid is 13 meters high against a midnight-blue background and with backlighting in places, the problems are difficult to assess visually. If on a 70 m truss you forget to engage even one of the seven motors spaced 9 m apart, it’s reassuring to know that the load won’t come down.

Philippe Coudyser : The specifications also stipulated that if, for example, Alexandre decided to integrate a load cell into each motor, the controller would be able to receive the load cell information and display the load present on each remote control channel, as well as on the remote.

On a group of hoists like those programmed here, we could have the indication of the total load applied on the truss, in other words the sum of all the hoists on the truss. And in the future, if the motors incorporate an encoder, we will also be able to manage altimetry: the program can evolve.

Regarding the intelligence aspect, this remote control also makes it possible to select the maximum number of hoists that can operate simultaneously, depending on the energy available upstream. You can make a group that will correspond to the available electrical power, without the risk of overloading the mains.

SLU : Is this remote control suited for touring?

Manuel Lauwerier : It works very well in a cabinet on sites with permanently installed motors with defined electrical characteristics. Sonoss regulates the current before the cabinet is delivered because the size of the cables depends on it.

It is important to know that each hoist of each brand has its own electrical characteristics, depending on whether it is double-reeved or not. These are questions that we ask when ordering. These starters are suitable for loads between 250 kg and 2 tons without any problem.

And if the hoists are smaller, adjustable hybrid starters from 600 mA to 2.4 A can be installed. In touring, on the other hand, the use of this cabinet would imply setting the consumption according to the motors before each performance. And if we set all starters to 9 A by default, the lower power motors would not be detected.”

SLU : Alexandre, you have chosen the wired version plus wireless…

Alexandre Trapon : As I was saying, it’s a tremendous advantage to be able to control the grid from the exhibition hall via radio, but here in front of the Eiffel Tower, there’s a risk of interference and, in the event of a radio failure, it’s once again reassuring to be able to use the wired remote control, as the cable is long enough to go down to the floor.

A cable connects one of the two control panels to the wireless receiver located in a corner of the lobby with its antenna – one is enough. And a cable runs along the floor from one control station to the other.”

Manuel Lauwerier : This remote control comes standard with a cable. To switch it to wireless, all you have to do is buy the receiver, as the transmitter is already built into the circuit board.

The Network

SLU : Are the trusses pre-cabled?

Alexandre Trapon : The trusses are wired with P1732A, multi-pairs, and fiber optics. In each of the technical rooms and on each truss I have a GigaCore 10 switch and Luminex nodes to connect the production equipment. Everything is designed to be easy and fast to use.

I have 12 fibers from the IT network that are routed back to the nodal point of the facility and, if necessary, allow a signal to be routed to the offices and vice versa. We have also planned to run the fiber outside for the OB vans.

SLU : What type of fiber do you use?

Alexandre Trapon : The fiber is basic single-mode for risk-free runs, while the trusses are done with tactical, military-grade fiber.

You can bend it 180°, even crush it, pull it; nothing fazes it. It costs an arm and a leg, but it is indispensable. We have used it for many years, and without a single failure.

SLU : Did you design the network?

Alexandre Trapon : Yes, with my IT manager for the specific network for production, as well as the gateway to the IT network. However, it was a GL Events’ Venues engineer who developed the office computer network, following the specifications, so that it would be as functional as possible. We drew up the specifications together with all of the relevant personnel.

There are four high-speed fibers for TV, we installed 3G and 4G antennas and we planned to install 5G as well, in addition to the WiFi component. The building is full of RJ45 sockets in order to run as few cables as possible. We assumed that a cable crossing the lobby wouldn’t be very attractive.

SLU : What lighting did you choose?

Alexandre Trapon : 95% of the fixtures are from Cromatic, a manufacturer specialized in the commercial sector. The lobby lights and the exterior lights are all controllable via DALI. The security manager has a tablet with which he can set the levels and choose the zones. The light can easily be dimmed zone by zone.

The statue of Marshal Foch is lit by Robe ParFect 150s in warm white. I plan to order them in full color if an event requires it. I have a small splitter that receives the signal and allows me to take control of these fixtures in DMX. I do my show, and when I cut the signal, the ParFects come back on in warm white.”

With events in their DNA, GL Events’ playing fields include trade shows, sporting events, like the Olympic Games, and many major international events around the world, such as the Conference of the Parties (COP), with renown expertise in power distribution, air-conditioning, audio, lighting, and networks. More recently, they have added architectural lighting and broadcast installations to their activities.

Alexandre Trapon, who has been managing the investments in lighting, structures, and electrical distribution for the group’s production activities since 2013, focuses on the long term with quality products sourced from reliable vendors, to whom he is very attached.

Alexandre Trapon : We need them as much as they need us, it’s a question of partnership. We know that events often require last-minute orders. Our relationships with our suppliers mean that they go out of their way to provide us with equipment.

Without this partnership relationship, the vendor would obviously be less attentive to the urgency of the situation.

Every year, we equip four or five festivals around Lyon, including Jazz à Vienne (except in 2020 because of Covid), and we invite our suppliers to attend because they are as important to us as our customers.

– Project developer: GL events

– Architect: Wilmotte & Associés Architectes

– General contractor: Hall Expo

More information is available on the websites of the GL events website and on the Sonoss website