Imagine following a sporting tournament, throttles in hand, in an Arena.

Imagine former gamers turned light operators, hands on a computer, with mind in networks.

Imagine that, at the slightest opportunity, young technicians rely on their RJ45s and tablets on the stages and on the TV sets.

Imagine now a distro techie in front of his racks, with all his lines deployed. Their daily routine is phase balancing, leakage current calculations or peaks surges management; a mathematics without the right to error.

Certainly the dimmed projectors have almost all disappeared, except that, between the management of LED power supplies, screen electronics or controlled motors, the situation has changed dramatically. A precision made compulsory by the security constraints when, at the same time, the potential sources of faults multiply.

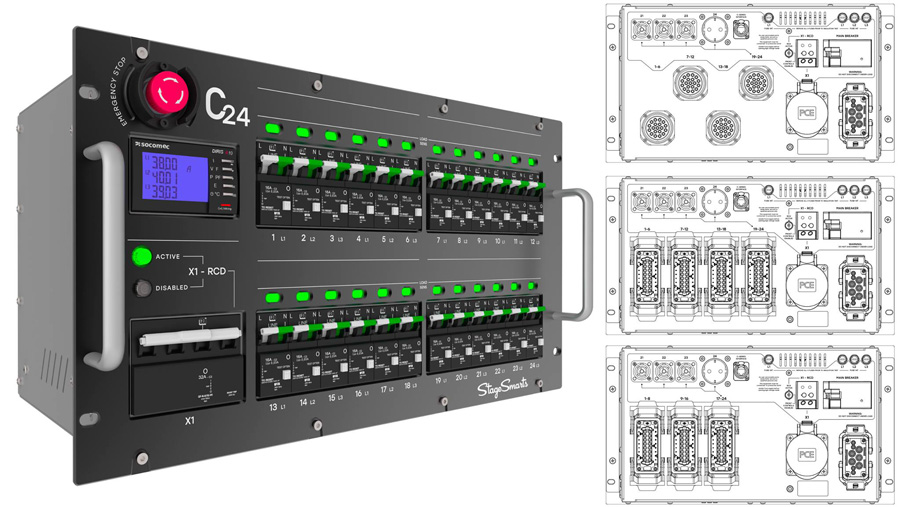

This has become the obsession of the Swedish company StageSmarts: imagine an electrical conversion with racks not really “smart” (they do not yet think by themselves!), but ‘expert’. Their expertise range from the quality of the differential circuit breakers to the real-time monitoring software. Thus were born the PDU 400 A cabinet, then since a few months a compact version in 63 A, in a concentrate of technology, the ‘new generation’ C24 direct cabinet.

C24 – Compact with 24 circuits

The cabinet C24 is a 63 A distribution rack with 24 circuits, 19 inch / 6U format, less than 30 cm high. A global reflection was conducted to save maximum space.

The general power supply, for example, is achieved via a reduced ILME 4-pole + Earth chassis plug, which will be used with an adapter to P17 or others. It is located, like all the connectors, at the back of the unit with its circuit breaker, leaving on the front only the circuit breakers of the outputs, the test screen and the emergency stop usual red button.

63 A power supply and 32 A output

For the input stage, the main 63 A Magnetic Thermal Breaker 63 A, or Main Breaker, comprises a measurement unit upwards to perform all tests before switching on. Moreover, it is protected by a transformer-rectifier capable of withstanding accidental surges.

On the monitoring display, the user can access, among other data, the currents (total and on the neutral), the voltages between phase and phase or between phase and neutral, the power in kilowatt per heure and the operating temperature.

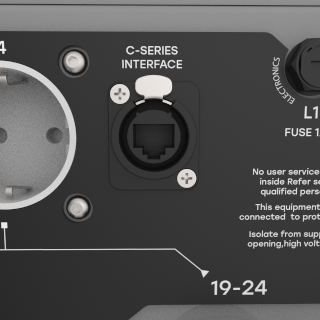

A complementary 32 A output via a P17 chassis plug on the rear, for an ancillary fixture. It is protected by a hydromagnetic differential circuit breaker with a separate differential circuit breaker, adjustable from 30 mA to 300 mA with test and reset features.

In case of use with specific loads, such as a motor remote control or LED screens, the differential can be deactivated by a locking key. This precaution is associated with an operation indicator located on the front panel, along with the 32 A disconnector.

24 independent 16 A outputs

Several configurations are available for the 24 direct output channels, on Harting 6 or 8 circuits connectors, Socapex 6 circuits, or on PowerCON chassis plugs.

In all cases, circuits from 21 to 23 are duplicated on PowerCON chassis plugs, while last circuit #24 is available on an IEC chassis plug. to be able to connect directly other small ancillary items.

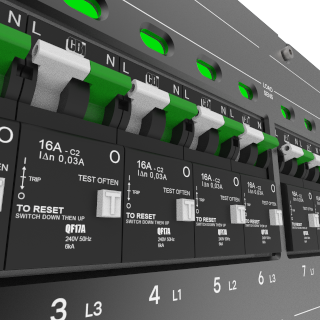

The 16 A output circuit breakers use high quality hydromagnetic circuit breakers against overloads, with a high tolerance against earth leakage, better power handling and total independence from ambient temperature differences. They work in B and C curves, in order to support the long cable lengths up to the projectors.

Each circuit breaker is grouped with a ground leakage differential for human protection and uses the 2 poles to be disconnected in total isolation.

They are very precise 30 mA differential circuit breakers whose tolerance threshold does not vary, and which will not be triggered at 15 or 20 mA after some uses, as might happen on other racks.

This protection (certainly more expensive) allows to use each output to the maximum of its capacities without worry, and to isolate them individually to avoid that a fault on one circuit might take down a whole multi-circuits installation.

For a better visualization of the problems, the circuit breakers can have three positions: at the very top, normal operation, in case of short-circuit they cut the mains and put themselves in a low position, in case of differential problem they cut themselves and stay in position average.

Control sensors and indicators are associated with each output, with load indicators to identify the state of the load at a glance.

If there is no load, the LED is off. In charge it goes green. In case of inrush current, if the circuit is approaching overload, the led will flash red. If this limit is exceeded the circuit breaker cuts out and the LED indicator goes red.

Safety and monitoring

Novelty brought by StageSmarts, very aware of what security means, is the protection against failure of the neutral. To prevent a relentless surge caused by the loss of the neutral, the system is able to detect any breakage of the neutral and will instantly trigger the ultrafast disconnection of the general power supply.

Built with sensors, the PDU 36/48/72 racks are integrated with control and management software. In the future an external control unit will also be available to control up to eight C24s.

The C-Series software allows you to view a large number of values from your computer. In real time will be displayed the load of each output, the supply voltages and currents, plus the neutral data, the temperature and the status of the main circuit breaker. In a serious accident, the data of the last 15 minutes will be kept for the further analysis.

The latest update of the SmartPDU software has, since this spring, undergone quite of a large number of patches and additions. It is thus possible to import and export settings in Excel list format. Voltmeter supervision is integrated.

Navigation is improved with several direct accesses. The power consumption per output is displayed and in total, the name of each output with the color codes of the connectors, then the list of all connected cabinets in fast display. Finally the erasure of the old lists and a total reset or in blocks become possible.

Utilization

This rack will naturally find its place in fixed installations to adapt to any kind of technical room, or in high-tech tours filled with projectors and LED screens, with strict requirements of safety and operation.

The presence of a differential per output and a preventive monitoring and data recording are very important assets, whose cost is not so extravagant to ensure operations without stress. The C24 will undoubtedly be particularly appreciated by new generation power management techies, navigating between the network, managing power supplies and constant monitoring.

More information on et sur the Stage Smarts website.

Some technical data:

Power input: ILME 4-pole + earth / 80A – TN-s 230/400V

Disconnector: 63A Doepke DHS4 NA

Measurements and tests: Socomec Diris A10

Multi-measurement:

Currents

– Instant: I1, I2, I3, In

– Average max.: I1, I2, I3, In

Voltages & Frequency

– Instant : V1, V2, V3, U12, U23, U31, F

Powers

– Instant: 3P, ΣP, 3Q, ΣQ, 3S, ΣS

– Average max.: ΣP, ΣQ, ΣS

Power Factor Correction

– Instant: 3PF, ΣPF

Counting:

Active energy: + kWh

Reactive energy: + kVarh

Hours:

harmonic analysis:

Harmonic distorsion rate (rank 51)

– Currents: thd I1, thd I2, thd I3

– Simple voltages: thd V1, thd V2, thd V3

– Composite voltages: thd U12, thd U23, thd U31

Channel outputs / 16 A : 24 x 16A on, at your choice:

4×19-pin “Socapex”, 6ch/connector.

4×16-pin “Harting”, 6ch/connector.

3×16-pin “Harting”, 8ch/connector.

3×24-pin “Harting”, 8ch/connector.

24 x Neutrik Powercon TRUE1.

24 x Neutrik Powercon (grey).

Protection : Differential circuit breaker CD1 Line RCBO type-A, 1 Pole + N 6kA 30mA

Channel output 32A : 1 x 32A on P17 chassis plug

4-pole disconnector + Siemens 5SV8000 RCD – 6KK, adjustable (30-300mA / 0,02-5 sec)

Dimensions: Rack 6U (483x266x354 mm)

Weight: 23 kg