TAF (Truss Aluminum Factory) launched its latest innovations and improvements at the ISE 2025 show. A Safety Lock system for its Tower 02 lifting tower, a compact rectangular truss, a brand-new tensioning system for the creation of fold-free roofs in RAL colors and steel feet supports on ball joints for all-terrain positioning of its TAF Tower 05 tower.

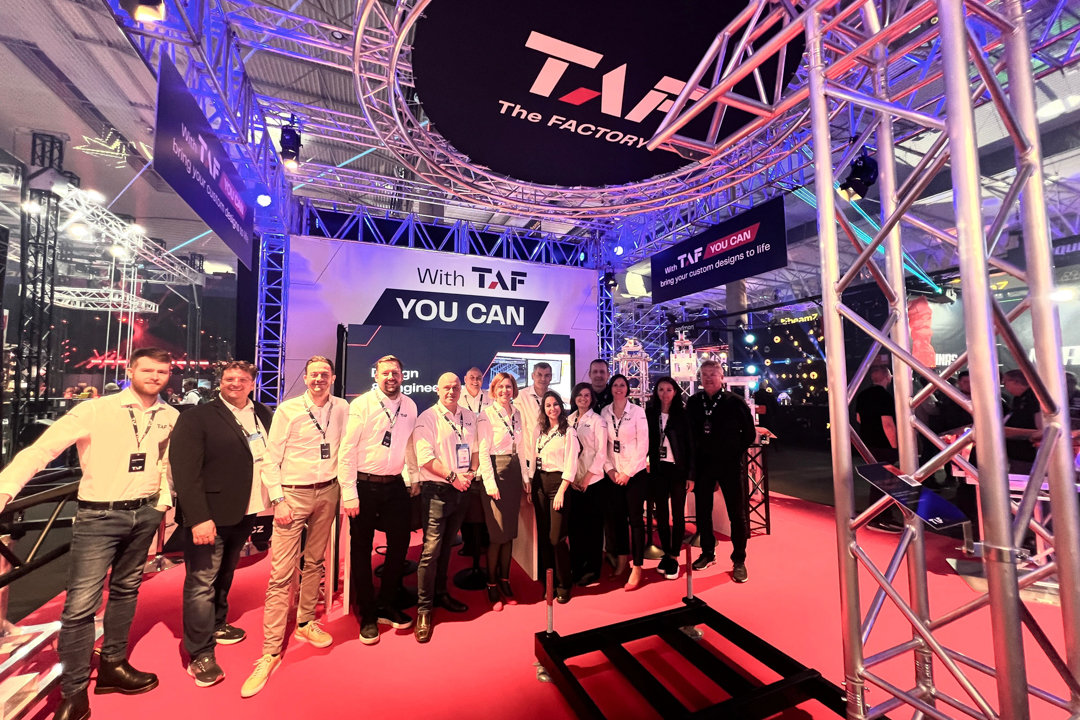

TAF, the European brand that is rising in the stage trussing industry and impresses us with the quality of its products manufactured in the Czech Republic by experienced welders, but also by a strong desire to make life easier for users.

Products from this manufacturer meet German TÜV certification. “TÜV verified.” The phrase resonates as a guarantee of seriousness in Germany in terms of verification and security. The Technischer Überwachungs Verein (or TÜV, association for Technical Inspection) is historically the first independent technical inspection entity in the country.

It is the competitor of Bureau Veritas and Intertek.” Source lemonde.fr. Load tests carried out every two years certify the quality and strength of the welds produced within the Truss Aluminum Factory.

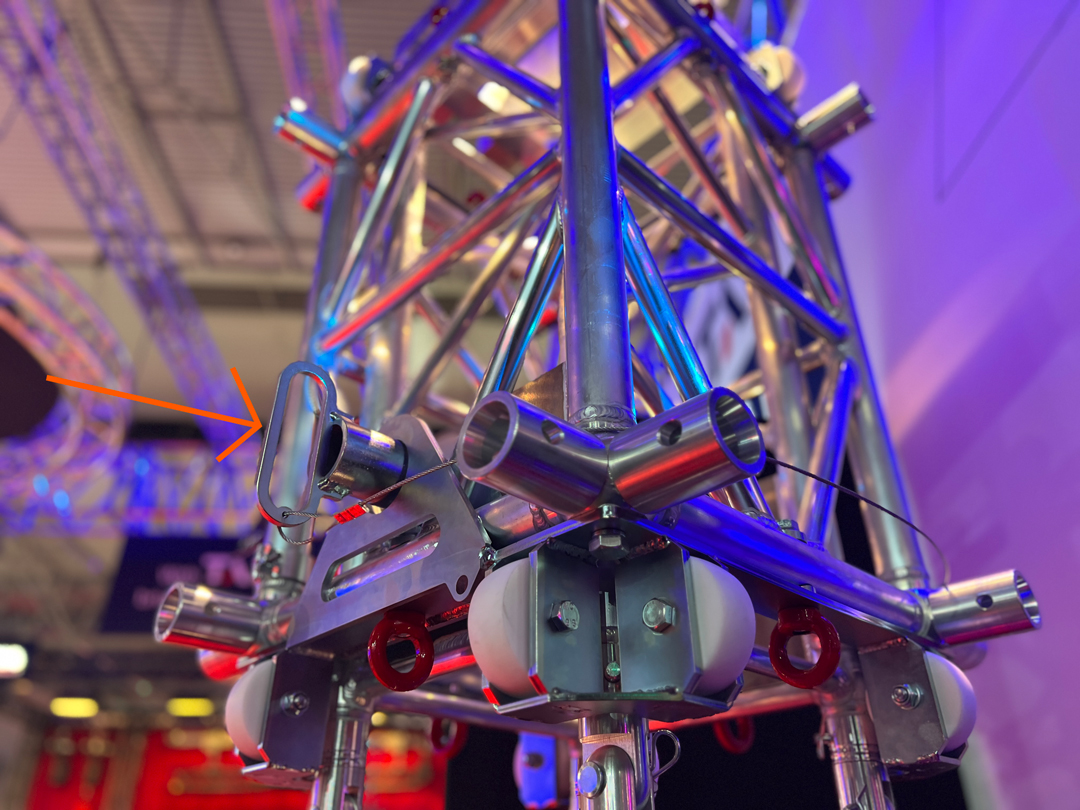

The Safety Lock System used by the TAF Lifting Tower 02

The new Safety Lock System from TAF is a safety locking system designed for the TAF Tower 02. It allows you to effectively and safely remove the weight of the grid from your chain or electric hoists from the base of the structure.

This three-part system consists of a safety lock tube (62 x 6 mm stainless steel), a Sleeve Block Adapter, and a Safety Lock Truss segment that securely attaches to the sleeve block.

Once the grid or the roof is raised to the top of the structure by the manual or electric hoists, you just need to engage the locking tube and then release the motors so that the whole structure is held by this safety system.

It is now available for TAF Tower 02 lifting towers whose specifications show a maximum load of 2 Tons and a maximum height of 12 meters. It is particularly suitable for structures/grids and roofs of larger projects or for supporting LED panel installations.

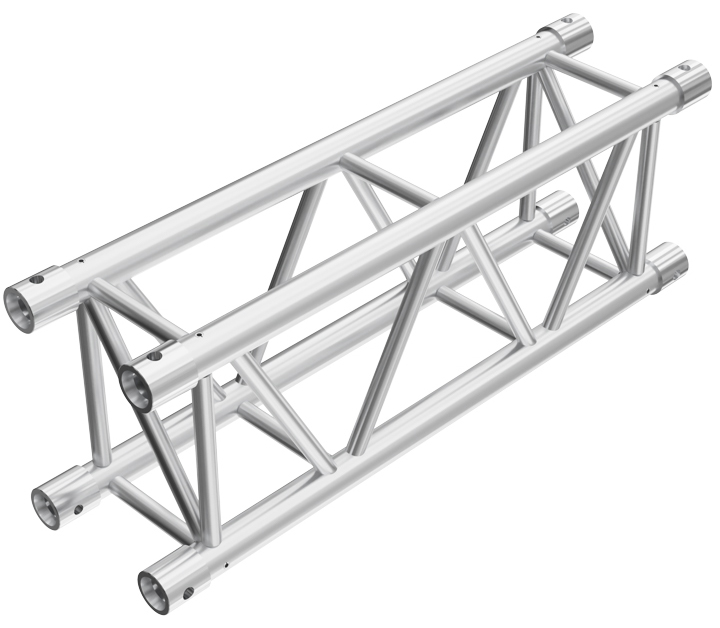

The new compact rectangular compact truss TAF TS36R

TAF also presented its new TS36R structure. Rectangular in shape, these are the smallest dimensions in the range (267 x 359 mm, 10.15 x 14.13 in). It is compact and offers high horizontal/vertical load capacity and great durability.

Compatible with conical pin connection systems. This range includes trusses and right angles. It can be used indiscriminately with Prolyte trusses like the rest of the TAF catalog. In addition, a powder coating to any desired color is available upon request.

.

The new roof tensioning system

To avoid any water retention or a rippling phenomenon due to poor tension of the roof fabrics, TAF has introduced a new manual roof strip tightening system that meet the demands of service providers and offers it in all the colours of the RAL colour chart. Here presented in RAL 6006 – olive gray.

This tension system is mounted directly on truss segments and is tightened manually using the wrench provided or an electric drill.

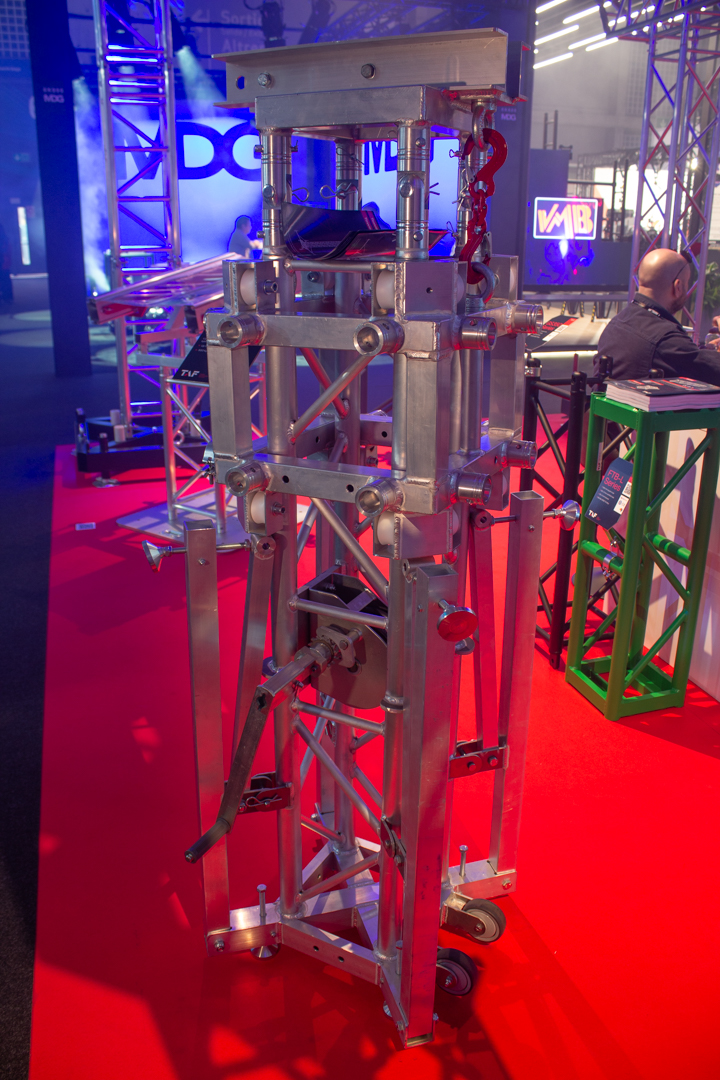

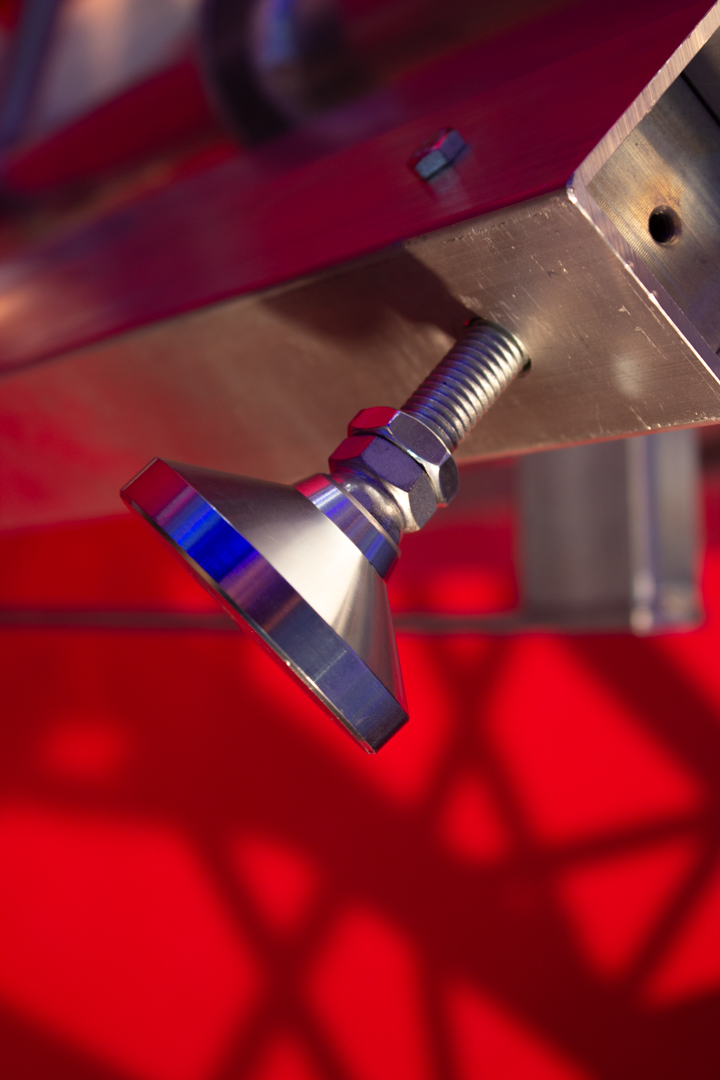

TAF Tower 05 all-terrain stabilizers with rotating supports/”feet”

To improve the use of the Lifting Tower 05, the TAF team, very attentive to its user’s needs, imagined a metal “foot” attached to a ball joint allowing them to carry out installations on uneven terrain. The “feet” can then adapt to the ground level on which they are placed.

TAF is launching this first prototype after a six months R&D test phase. Initially, this system is only available for the TAF Tower 05 wheighing in at 100 kg on the scales, can lift up to 6.5 meters high and support a maximum load of 500 kg.

This tower is perfectly suited for roof support, LED screen walls, light lighting kits or even DJ Booths. It is manufactured from 6082 T6 aluminum alloy to industry standards and uses steel for certain parts for maximum strength.

.

For more information on TAF, you may visit the following :

– Their website which also presents a blog of projects using TAF structures

– YouTube

– Instagram