When we carry out a moving light bench test, we are concentrated on the light output, the possibilities of effects, but also its ease of use and installation, in other words the hanging system provided by the manufacturer.

Since we are often the actual users of the fixtures, we are going to take a look at the rigging(hanging) possibilities and the importance of the little piece of metal used for adjustable clamps

The hanging of these fixtures has always been of major importance for the manufacturer and the user. Mainly for security reasons.

The use of these clamps called “Omega” (their shape is that of the greek letter Ω) because of its easy mounting and dismounting on the fixtures using the cam-lock ¼ turn system has made these clamps the norm.

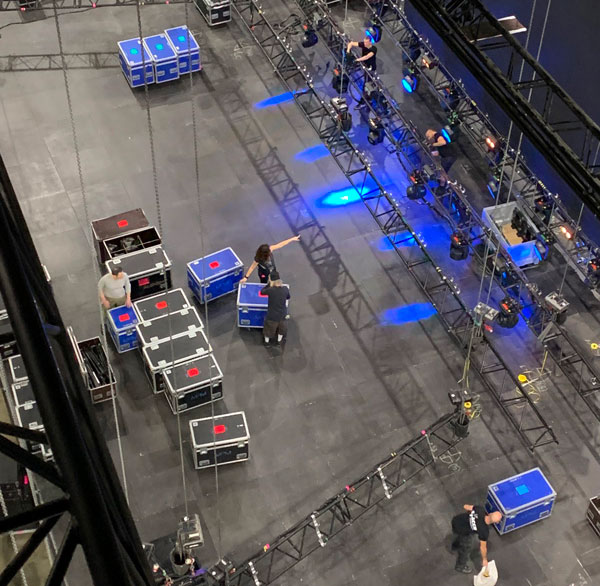

What a breakthrough! Even though it can take a bit of time to install them on 20, 40, 60, or more fixtures during load-in and likewise when loading-out of the venue.

Installing the fixtures on pipes or different sizes of trussing is when the problems usually arise…the lighting plot and the positioning of the fixtures must be respected, however at some point it will be impossible to place a fixture correctly because of a crossbar or other “obstacle” (rigging point of tube or truss, point of assembly of the truss sections, etc…)

It is often considered a minor problem (however not being able to install the fixture directly overhead of the musician it is meant for, can be a problem) for conventional lighting fixtures because it uses a single clamp. Most moving lights use two clamps can make it a bigger problem more often than not.

In practice, we often shift the projector a few centimeters or more, when possible. We also shift the lead position by a few centimeters and no one sees anything…Mmm, I guess so… But no. It’s not always that simple…

And above all, it doesn’t always concern a simple lead position, nor necessarily a few centimeters… It can concern several fixtures, and the precision of their positioning can be extremely important. Whether it’s in the center (lead position)or not.

When it comes to fixtures aligned, a shift of a single machine, even by a few centimeters (and even more so when it is sometimes 10 or 20 centimeters, approx. 4-8inches), can be a big problem, even unthinkable.

I’ve had this happen several times myself, notably on a show where I had 8 Beams lined up, used together at the same time, pointing straight down… If you offset one of the fixtures by 10 or 15 centimeters, the effect is completely spoiled.

And I can tell you that faced with this problem, when the local crew shows you the fixture that is offset, with a tear in the corner of their eyes waiting for a “yeah it’s good, who cares, it will be ok like that” on your part, it’s difficult to request everything be taken down. Then find an appropriate spacing for the eight machines, that will work with the truss in the venue… But it happened to me… And we had no choice…

Sometimes the solution is simply to offset the hanging position with a tube and clamps to allow precise positioning across the width. However, this solution will affect either the depth or the height of the hanging point, therefore creating an offset again.

Let’s not forget that sometimes, on large folding trusses, for example, we may have to shift a machine 40 to 50 centimeters (approx. 20 inches) from the planned spot! (I have already experienced that !) And so sometimes, we saved time and energy for everyone because we had machines equipped with adjustable omega clamps!

But what is an adjustable clamp exactly?

These are omega fittings with clamps that can be adjusted across the width. It’s really convenient. This makes it possible to avoid an awkward spacing on the truss, or even to spread the two clamps to avoid the trussing assembly or a technical obstacle.

The fixture can also be hung with an offset to one side, or the other, of the center point.

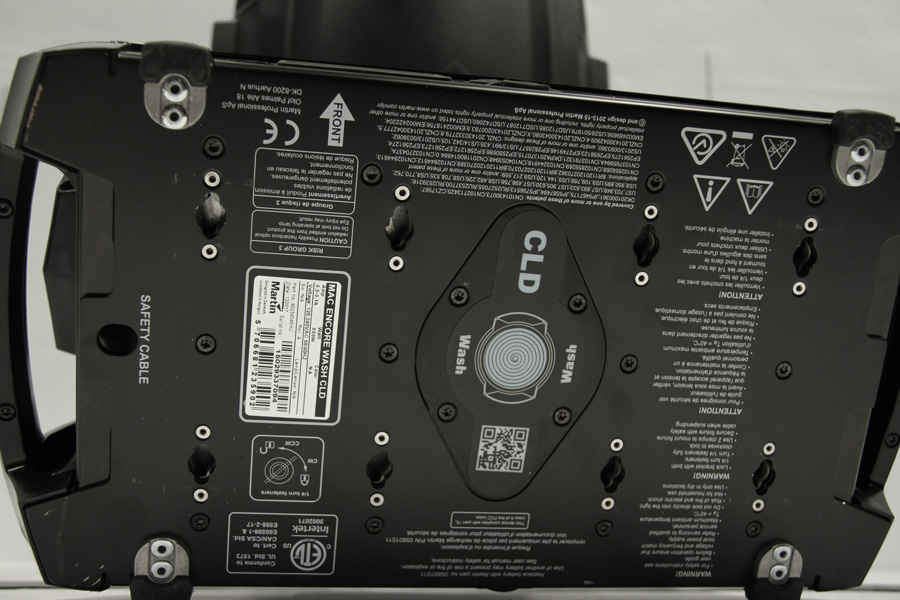

It was Martin that developed first this type of clamp in the 90s, followed by Clay Paky made available with its entire range of Alpha fixtures. The same for DTS. Robe proposes them as an option. It is sad to say that there are still a lot of manufacturers that supply only simple omega clamps…

I know that personally, even if it is not my first concern, this detail counts in my selection of machines. Because I know what a waste of time it can be to find compromises of symmetry and positioning that will “pretty much mess things up” in the long run.

On the market of moving lights, adjustable omega clamps come in several forms. The simplest system has a drilled offset piece of metal or “tab”. (Photo A) Simple and effective, it allows you to choose between several combinations of positions.

The other system, even more flexible, is the one that comes in the form of a slit or “channel” allowing the clamp to slide over more than ten centimeters (approx. 4 inches). (Photo B), and offering a large choice of positions.

This system is optimized in the hanging kits of some led bars or led panels we can no longer call it an omega. (Photo C). As we are talking about fixtures whose effect is largely made obtained by the precision of its positioning and hanging, the manufacturers had no other choice. !

Note: some fixtures are provided with several choices of positioning simple Omega clamps under the base unit, which offers several possibilities of combinations (Photo D). But this solution, although already a step in the right direction, turns out to be less flexible and less practical in daily use than an adjustable omega.

I think that a number of us expect manufacturers to adapt their machines to user needs, not only in terms of light, type of effect, gobo kit, and colorimetry, but also for everything related to the installation, packaging, ergonomics, and everything that makes their fixtures offer complete satisfaction to all the different trades that use them.

If the directors of photography or designers have expectations, if the business managers of rental companies have others, the technicians who deal with hanging problems on a daily basis also really need to be heard. It would be nice to ask them too.

I am nevertheless convinced that some manufacturers are barely aware of this problem and have probably never had any feedback on this subject…

The adjustable omega clamp, is a simple accessory, just a piece of metal….but what a time saver!