After consolidating, in 2020, several buildings and workshops spread out here and there with the growth of the company over the past 30 years, the new FOHHN complex in Nürtingen is in the countryside just a few kilometers from Stuttgart.

All the resources necessary for the development and effective operation of this German brand are within this group of buildings as explained by General Manager Jochen Schwarz, and the co-founder Uli Haug.

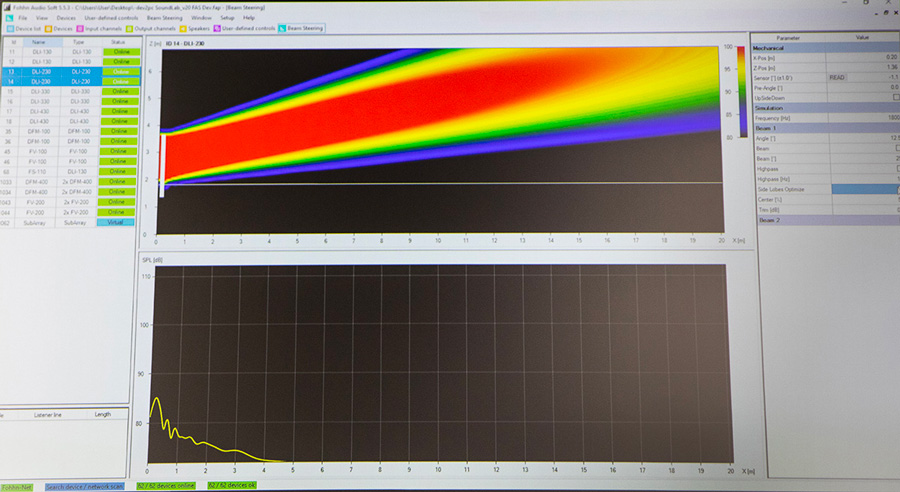

The showroom or SoundLab is the hotspot of the building complex, accessible directly from the FOHHN welcome desk and bar. It contains their entire line of equipment, ranging from the small LX-10 cubes to the Focus Venue, as well as the speaker columns with their controlled beams, that made the company’s great reputation, and also the more traditional ones. Any of them can be listened to using a matrix system.

Another nice surprise, rigged to the ceiling and behind an acoustic fabric, are 60 coaxial passive CLT-201 speakers, a specific expansion based on a 10” and a 1,4” driver in a square and shallow wood enclosure. These speakers are perfect for immersive in the SoundLab via a WFS Iosono matrix made by Encircled Audio.

Four 18” subs, one in each corner, complete the setup and provide a solid foundation for the great demonstration by Ralf Freudenberg, a veteran of TV mixing, in love with sound and the FOHHN products.

Last but not least the SoundLab profits from a solution called Vivace by Müller-BBM, creating active acoustics based on generators of convolution reverberations and a recording and regenerating matrix of the room acoustics. May it be mentioned that Encircled Audio and Müller-BBM are both German companies, keeping it in the family…

After this, more than successful kickoff of our tour, we are on our way to visit the entire building complex, the assembling building, the parts management warehouse, the warehouse with the finished products, the Research and Development department, the administration offices, the customer area, and the training rooms.

The only place missing in this Fohhn tour is the torture chamber, a room behind the R&D department where the speakers are shaaked and mistreated in tests leading to their destruction, electronic and printed circuits reeking of burnt varnish. Maybe next time.

Samuel Hartmann and Nico Schwarz were our guides, and underlined the durability, energy efficiency, and reduced use of raw materials that were a major factor in the complex, pointing out the heat pumps recycling the heat from certain ovens, and other heat-producing machines and using it to warm the outside cold air in the winter, and pump it back into the workshops. This was a major investment for the German company, they are very proud of it.

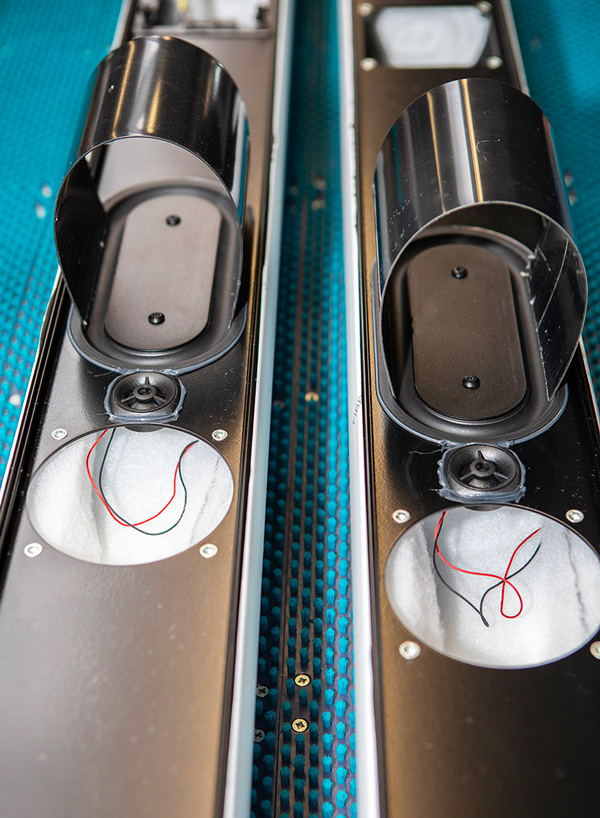

The essence of FOHHN products, multi-amplified for the most of them, is what makes this visit in the production and assembling workspaces quite different from the regular passive speaker factory.

Electronics are everywhere, and the trays of amplifiers, mains modules, and DSPs are full, making the final assembly more complex, hence more time-consuming.

FOHHN has a long-term approach. Their amplifier CMS modules are designed and the scale models done in-house, and then they are built by a German sub-contractor as physically close as possible.

The same is valid for the wood workshops, all of the speaker cabinets arrive ready to be fitted with the transducers and the final assembly. Before a series is put on the market, all of the glues, primers, absorbers, foams, and metal grids, are tested in Nürtingen, the final products go through the heating chamber and then to the torture chamber, before approving each model of every line of available products.

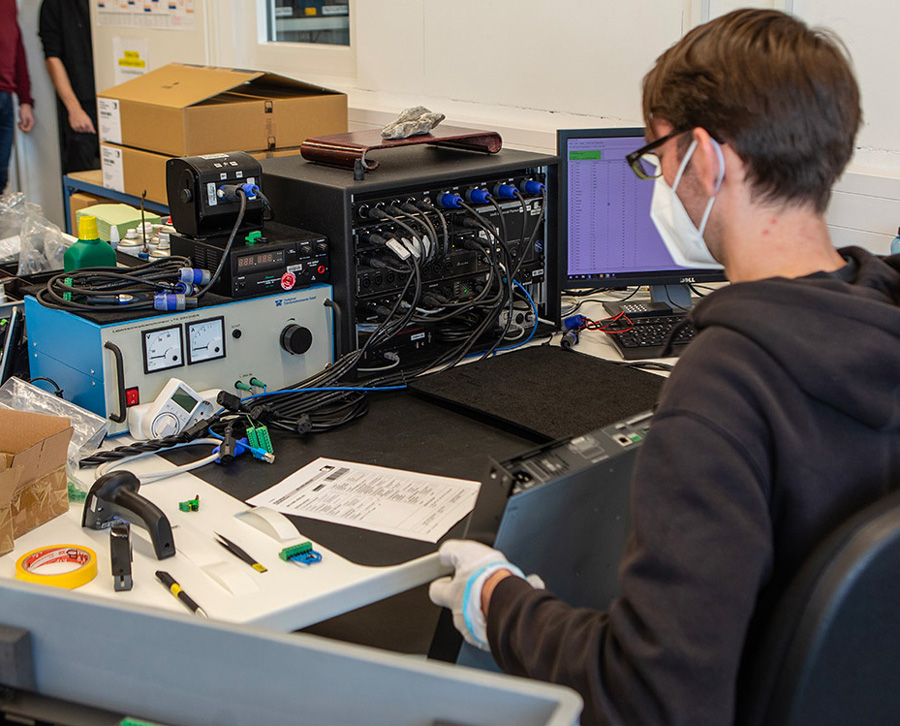

“The amplifiers after being assembled and put in racks, go through tests, a burn-in period where we try to create problems, like overheating, for 24 hours. This enables us to locate 98% of the faulty components.”

Following is a group of complete semi-automatic tests lasting 8 minutes, every value is tested with a lower impedance load than required by the amplifier, then short-circuiting tests and finally some music is listened to.

Obviously, all of the speakers, without any exceptions, go through the tests once the final assembly is done, and then a double automatic test via a measurement microphone to test the frequency response, phase, and distortion, and it all has to fit in this tight and precise template per model.

Then using very low frequencies for a short time to shake any loose parts in the woodwork of the cabinets, or the transducer moving parts, then a few minutes of music is listened to. A wide variety of adaptors allows for any type of speaker to be tested.

A second bench test is in the works to speed up the deliveries. All of the data of each tested product: active, passive, amplification or other is stored in a server to enable any tracing of a product or any other data use if needed.

As a reminder, FOHHN produces 15 000 speakers per year, taking into account all of the different models.

Leaving the Production & Quality Assurance building, we head to the Logistics Center & Stock, where the 6500 references and 3 million parts are ready to be assembled, and also the stock of finished products, tested, packed, and ready to be shipped around the world.

The number of boxes in piles and pallets covered in the plastic film is proof of a large order being prepped, the order made by MSC Croisières finishing the construction of the MSC Euribia at the Saint-Nazaire shipyards, a new generation of cruise ship using LNG (Liquified Natural Gas) propulsion system.

FOHHN has a very extensive catalog and has become, in the last few years, a privileged supplier for maritime integration specialists, such as Videlio.

We now leave the logistics building to visit the R&D, with a test underway, as already told we could not visit the insides of the Durability Testing, the room devoted to all of the “destruction” tests and those that survive 100 hours of continuous pink noise.

Each loudspeaker in its project phase must pass this test before the model can be approved, and the series launched. Thermal cameras are used to detect what parts output the most calories that could impact the lifespan, there are also smoke detectors and automatic fire extinguishers just in case, that can even send an SMS if they have been triggered at any point.

We now visit the two soundproof rooms, both can be used even though one of them is not completely fitted with anechoic material. The smallest room can measure as low as 35 Hz.

The biggest one can measure frequencies down to 25 Hz, but it’s is used mainly for the 500 Hz to 20 kHz ranges to study the dispersion of the waveguides. To do this, this chamber has a rotation system to measure and create polar plots.

The roof of the Nürtingen building is equipped for potential free-field measurements, but like other manufacturers, FOHHN is forced to move a few kilometers away to an airfield in order to work on its presets and to have full power listening without disturbing the neighborhood too much.

FOHHN Optimizer

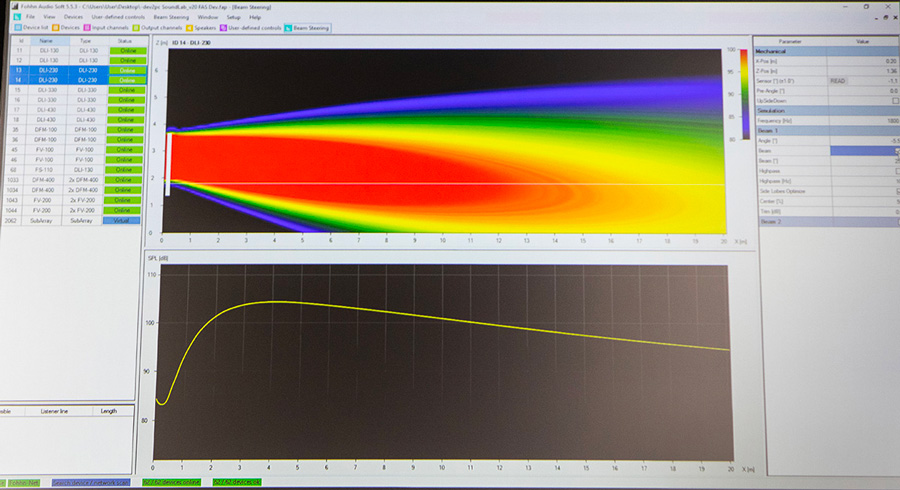

Upon returning to one of the rooms used for apprenticeship/demonstrations/meetings, we are given a demonstration of the FOHHN Optimizer and fully functional. It is very practical and available at: www.fohhn.com/en/products/fohhn-optimizer/.

The idea behind it is to calibrate one or more speakers, taken from the FOHHN catalog, using a web page, and as simple as can be via a smartphone using, if possible, a small microphone plugged into it, such as the MicW for example.

Measuring a pink noise at different places in the room, close-up and further away, and the job is done. The resulting snapshots are integrated into a unique correction proposal sent directly to the DSP of the amplifier.

It is possible to lessen the proposed attenuation, not to drastically reduce the speaker’s energy using a less academic curve. In any event, the result is convincing and very helpful for the system integrators, in simple setups, if there aren’t sound technicians available to perform the analysis and manual settings of the sound system.

For more information, watch this video in English

Interview with Jochen Schwarz

At the end of our tour, we had the pleasure of spending some time with Jochen Schwarz, General Manager of FOHHN, Uli Haug’s longtime accomplice. We would like to thank him for his time, honesty, and sense of humor!

SLU : How long have you and Uli been accomplices?

Jochen Schwarz : It has been 30 years. I was a musician in a band with his brother and one day we needed someone to do the mix. Uli arrived with his brother to look after the sound desk. I was 18 years old at the time…Following that day we toured together for more than 10 years, I was on keyboards and he was at FOH desk, and often had to use sound systems he didn’t like very much.

“Hence we decided to build our own sound system, with the help of a friend, a simple plug-and-play one, the complete opposite of piling speakers one on top of each other, that was the trend at the time. At the same time we built the EasyPort system, easily mobile, practical, and user-friendly.”

SLU : However, while being musicians, you were all studying…

Jochen Schwarz : “Certainly, I studied mechanics and I am an engineer. My goal has always been to combine music and the technical aspect, during my schooling I continued to perform in concerts (smiling).”

SLU : What about the beginning of the company?

Jochen Schwarz : “One day we rented a large building for rehearsals before recording a CD and we invited a friend of ours, who was developing our speakers, to come along. Not only did he join us, but he also offered to show our products at the upcoming Prolight+Sound. We didn’t even have any brochures yet; nothing (laughter). We received our first orders, which were filled by 1993.”

SLU : And what about Uli?

Jochen Schwarz : “He was just at the beginning of his studies and we promised each other that if I started a Company he was to join me. This was sooner than we expected, during his studies, we saw him every day !”

SLU : FOHHN was born almost thirty years ago. After the EasyPort, what was the next product that came out of your workshops?

Jochen Schwarz : “Some multipurpose speaker columns, that could be used for either music and/or speeches. These versatile speakers were greatly appreciated by the churches. At that time they were using a PA system solely made for the talking voices and had to hire other systems for concerts taking place. We often performed as a band in many churches and it was very complicated every time (laughter).”

SLU : Did you receive a lot of work with the various houses of worship?

Jochen Schwarz : Yes and to this day they still are a non-negligible part of our worldwide sales.”

SLU : Where did you get the company name from?

Jochen Schwarz : “It comes from the subjective measure of sound level, the Phone or Fon. It’s an imaginary word derived from the two ways of spelling it and we added an H. FOHHN.”

SLU : When you started your business venture, what was your goal? What was your motivation..?

Jochen Schwarz : “Playing music (laughter). Seriously, it’s exactly what we did on our stand at the PL+S, and since we didn’t have any mikes, we went to see AKG to ask if they could lend us one.

This created a sort of friendship that later led us to become sub-contractors for this major company and produce hundreds of MAXModulars, which also taught us the different manufacturing constraints with OEM in terms of quality control and uniformity.

We grew and moved to different premises at least twice over the first ten years to keep up with demands.”

SLU : The team has expanded…

Jochen Schwarz : “We were lucky to welcome right from the start, two very important people for the development of our products, and very good musicians too!

Bernd Nimmrichter head of our electronics R&D and Boris Kunz mechanical and acoustic development manager. They made some great products, good music, and even some nice lighting bars for their bands (laughter). They know how to make everything and/or anything. This is how we positioned ourselves as: systems for musicians.”

SLU : You set out to tackle an industry that already had many competitors…

Jochen Schwarz : “Oh yes, especially German, American and British manufacturers. Yet we were young and our business plan was our courage and our ideas. Nowadays I don’t think it would work in the same way !”

SLU : What is your claim to fame?

Jochen Schwarz : “When asked if we were known, the answer is often: “yes, we have an EasyPort in our stock.” This small Plug & Play speaker was our fame and was also copied by a well-known German company !”

SLU : Were other major brands jealous of your success?

Jochen Schwarz : “Yes quite a bit. We won’t call names but we weren’t always very welcome. We learned to work around the major companies and their catalogs, to find our niche and specific clientele.”

SLU : Did FOHHN have a steady growth/development?

Jochen Schwarz : “Yes, on average it was more or less 10% a year. We realized quickly that to even it out we had to be able to supply a complete system, and with Plug & Play integrating the speakers, amplifiers, and DSP that were all separate at the time. Houses of worship, for example, wanted discrete integrated solutions.”

SLU : DSP, is your magic word…

Jochen Schwarz : “It dates back to 2004. Bernd Nimmrichter came into my office and said: “I need a development kit to learn how to draw and program digital audio”. We bought the development kit and he started to imagine the Beam Steering system. “We can control the sound, guide it in any direction using multiple transducers. I also need a DSP”.

Over the next few years, we developed the technology and created the necessary DSP modules for our early models of speakers and the software to give us hands-on control of our products. We quickly presented models with a built-in screen, which received some mockeries.”

SLU : Did you also build your own amplifiers?

Jochen Schwarz : “No, we came to an agreement with Powersoft and used their modules and inserted our own DSP cards.”

SLU : The DSP products are a big success, I imagine that you must have needed to move to new premises once again…

Jochen Schwarz : “Growing by 10% each year, every 7 years we have doubled our output, so yes, we did move often and lately we had up to 7 different buildings simultaneously, a logistic hell.

We are thrilled to have been able to almost entirely auto-finance and build our own complex here in Nürtingen, true to our image and values.

It is a dream come true that took 10 years between finding the right land plot and having the entire complex up and running. We needed a lot of space, a flat plot to not have any different ground levels between the different buildings, an environment with very little noise for our sound readings, surrounded with greenery for our well-being to continue being creative, and also very close to Stuttgart.”

SLU : How did you get set up in this magnificent space, wasn’t it finished during the pandemic?

Jochen Schwarz : “The moving-in took place in January 2020, in the parts that were finished, the offices, the logistics area, and the assembly areas, the customer welcoming space, and SoundLab were finished later.”

“It was tough. However, the German government helped us out, to avoid laying off employees and being able to employ part-time, or work-from-home and also with a cash loan that we didn’t use in the end.”

SLU : The Covid period was financially difficult considering you supply mostly system integrators?

Jochen Schwarz : “In 2020 we lost 15% of our sales revenue, in 2021 we were back up to our regular sales revenue. FOHHN is a very nimble company and follows the market’s needs. We were able to point ourselves in the right direction and compensate for the change in the pace of some models and technologies. We did well and also had a bit of luck. Other bigger companies didn’t make out as well as us.”

SLU : What makes up the FOHHN DNA, what are the company’s values…?

Jochen Schwarz : “First of all its team has always been like a family, and then the technology, ideas, and the good vibes. We are not just another manufacturer, but a company based on its women and men and the ideas that provide solutions for audio, always innovative and user-friendly for the system integration market.”

SLU : Recently you have put some products on the market that seem to be for Touring, such as the Focus Venue and/or your latest passive subs PS-800 and PS-850.

Jochen Schwarz : “On MSC cruise ships, in the ZDF studios, and elsewhere these big products are easily integrated.

We do not specialize in Touring equipment, however, we feel the need to offer big sound systems. We supply clubs in China that are gigantic, where double 18″ speakers are a must.”

SLU : A few years back, in your catalog, there was the PS-9, a sub using an Ipal 21″ transducer, and an amplifier using very low impedance by Powersoft. Why did you stop its production?

Jochen Schwarz : “We developed and designed our own amplifiers for over 6 years, the DI, which allowed us to produce our subs and end our “deal” with Powersoft.

We have been around for some 30 years and wanted to be in total control of our technology. We have the know-how and the designers to build almost everything in-house here in Nürtingen. It also makes it easier to adapt quickly to a situation, which was very useful during the pandemic.”

SLU : FOHHN has a very extensive product catalog compared to other companies. Is this intentional and useful?

Jochen Schwarz : “Certainly. When you compare system integration and touring, the first requires a wide variety of solutions and models to adapt to every different project, whereas for touring they need ones that can have different uses, and if possible, the same ones for most of the hire companies so they can combine their stock with others when needed for big events.”

“At FOHHN we go as far as to cut the speakers to the perfect size, and we can supply any color and all types of different finishing…That is how we started, by doing what the other brands refused to do.

At that time many major brands would say:”…you can get this model in any color. Mainly black.” If MSC Cruiselines asks us to design a specific system for one of their ships, we can do it. Tailor-made equipment is our strength, which other companies don’t have.”

SLU : How many cruise ships have a FOHHN acoustic system?

Jochen Schwarz : “At least eight cruise ships, and a certain number of ones that were upgraded. This specific market led us to come up with extra flat speakers, because onboard every little space counts. Space is a luxury.”

SLU : You have also been climbing on board in the Business Communications sector.

Jochen Schwarz : “We had started to look into it even before the pandemic, there was a real problem with the sound quality, during the visio-conferences, and in general it also applied to meeting rooms, amphitheaters, and all buildings welcoming visitors.

Supplying good quality sound in these places is a future market.”

SLU : What is FOHHN’s average sales revenue and how does 2022 look?

Jochen Schwarz : “It is 14 million Euros. 2022 is off to a good start. Our financial forecast is the best one so far. All we have to do is produce and deliver the goods. There is quite a big shortage of certain specific electronics that are needed for our amplifiers.

Up to the end of the first quarter of 2022, we had enough stock on site, however, it is not the same now, more and more types of parts are going short also. For the Dante, becoming more and more scarce, the next delivery of essential components is not for at least a year…It’s dangerous for our entire industry, we also have orders waiting for speaker systems that the clients want to be delivered only after receiving their sound desk which is also late !”

SLU : The war in Ukraine, will it have a lot of negative effects on FOHHN?

Jochen Schwarz : “That is a possibility, considering Germany is very dependent on Russian natural gas, electricity costs have taken a huge jump. For 2022 our electricity bill will cost us 50 000€ more. Microprocessor foundries also need specialty gases, so this only makes our supply more complex.”

SLU : To finish up our lengthy interview, we would love to know how your duo with Uli works. What are each other’s qualities and how do you function on a daily basis?

Jochen Schwarz : “First of all we are friends. We share our ideas, often the same ones, and our “feel” about things every day, sometimes even during the weekend! We work as a tandem, in this very complicated world, we would be crazy not to.”

“Uli is very good in everything to do with sales and marketing, while I prefer looking after the administrative and strategic side or, for example, the construction of our building complex in Nürtingen.

Our differences are what unites us. He is 100% on sales and our clients, and I am more into our company and our means of production, technical aspects, and our human resources. We don’t tread on the other’s turf, we complement each other perfectly. A great team, we both give each other a friendly push when we feel we are “spinning-our-wheels” and not moving forward !”

SLU : How many people work for FOHHN and how is your workforce spread out?

Jochen Schwarz : “We are roughly 75, and there are also around 25 people working for us at our subcontractors. So, we have split the approximately 100 people into the following sectors: 25% in administration, marketing, and sales, 25% in R&D, and 50% in building our products. Finally, 8 collaborators are working for FOHHN in other European countries.”

SLU : And in conclusion?

Jochen Schwarz : “I think that our new premises give us that extra strength and allow for more production as never before. We can reinvent ourselves here, especially after the Covid slowed us down for two years.”

“When Uli asks his client’s why do they buy FOHHN products, the answer is often the same: the quality and the people. We are aware that other companies have the know-how to make just as good products as us, however, we make a difference with our human contact that others have seemed to have lost a little.

I hope that we will be able to keep it this way as long as possible, be wary of growing too quickly, and/or investments being too binding.

Any product can be copied, but not the team nor its mentality. We don’t have machines or robots, just men and women who are the one and only wealth of FOHHN.”

One of these men and a great communicator, Chris Bollinger, offers you a video tour of the premises here

And for more information on the Fohhn website