As lighting manufacturers continue to push the boundaries of what is possible in luminaire technology, the practical application of that technology falls upon the designers and technicians.

With many different lighting designs and a myriad of applications worldwide, not all designs require the same characteristics from fixtures in their rigs. While a studio lighting design may require one fixture attribute, a concert touring design may require another. In these instances where specific performance capabilities must be available, it is the cooperative relationship between designer and manufacturer which plays a critical role in the overall success of a design.

“This really goes back to the fundamentals of lighting design and what it is that lighting designers truly want,” began John Featherstone, Lightswitch Partner and Principal. “For a lot of applications, the quest for a long time has been for the flattest field possible. If you are lighting scenery, doing gobo projections or want a nice, fat beam of light in the air, a flat beam field is optimal. Conversely, there are also a lot of applications where you really want a distinct 2:1 aspect ratio peak field.”

Understanding the contrast between a lighting application that requires a peak beam field and one that demands a flat beam field is crucial in the fundamentals of design. Knowing exactly when and where to deploy fixtures that will give you the ideal beam field necessary allows a designer to create the most advantageous visual experience.

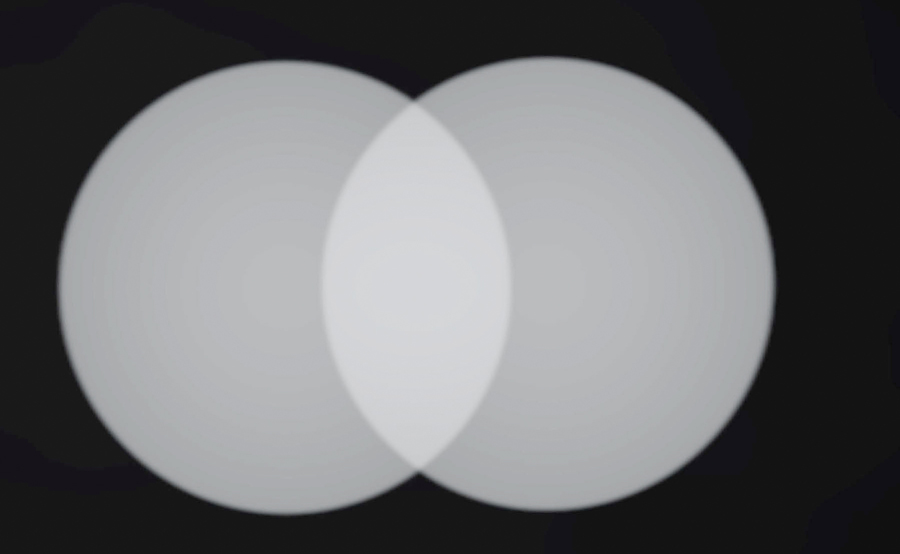

“Based on the simple law of physics, if you’re creating adjacent areas of light on the stage and you have a perfectly flat field, you will have light doubling where those areas overlap,” continued John. “This then produces a very uneven, or a difficult to make even, light distribution.

On the other hand, if you have a 2:1 center edge to beam fall-off, when you overlap the edges of those beams, you get the same amount of light where the two beams intersect as you get in the middle of one.” “Looking at the various lighting designs which a designer may be asked to create, in 90% of cases, a nice flat field is exactly what we want as it’s sort of the gold standard for optical distribution,” added John.

“However, when we are using automated fixtures to do a stage wash, we really want a peak field so that we don’t get any light doubling. This is something that has been the Achilles heel of any kind of moving light, especially for theatrical and television lighting. On a concert tour where you have artists moving about the stage, it’s not a necessity, but if you are doing a TV shoot, theatrical production or a corporate event, it is absolutely critical to achieve an even stage wash.”

“Traditionally with moving lights, an even stage wash has been accomplished by using a fixture model that only does a peak beam field or one which offers an interchangeable peak beam reflector for arc sources,” admitted John. “The challenge with this is the amount of work behind it as you have to dissemble the light in the shop creating inventory management challenges, and anything that costs money to the shop, costs money to the show.”

Seeing the need for fixtures that could provide designers with both the peak beam field and the flat beam field desired, automated lighting manufacturers have struggled to develop an ideal solution. Wanting a better option in lighting technology, he knew he would need to work collaboratively with a trusted lighting manufacturer. As the Czech Republic-based Robe Lighting was introducing its latest automated LED luminaire, the team at Lightswitch took this opportunity to see if they could make the solution a reality.

“Josef Valchar, CEO and co-founder of Robe Lighting, asked us about our wish list during an evaluation of an early prototype of the current generation LED Profile luminaire” explained John. “In true designer fashion, we said we would like a fixture that could produce a flat field when we wanted it, and then also a peak field when we needed it. Essentially, we wanted to have our cake and eat it too.” Unbeknownst to John, Josef not only heard this request, but he decided to act upon it as well.

Believing in the importance of providing designers with the fixture choices that will truly impact their designs, Josef worked with the Robe optical design engineers and created an innovative Hot-Spot Lens System for the ESPRITE™ and T1 Series of LED profiles. The new lens system accessory was also successfully tested in previous generation Robe LED profiles, and will continue to be implemented in future product releases when applicable.

“To our delight, Josef took our request and developed a Hot-Spot optical device which fits perfectly into one of the rotating gobo wheel slots of the new ESPRITE™ and offers designers the option to literally have a drop-in peak field reflector,” said John.

“Now when we are doing a corporate event and lighting the stage with the fixtures for key light, we can have a peak field distribution, but if we are creating an entertainment design or want to use gobos with the same fixture, we can drop that peak field reflector out and get a nice, flat field beam distribution.”

The new Robe Lighting ESPRITE™ LED is a fully featured automated luminaire that has a fast-change, low-cost, transferable light engine which ingeniously solves the problem of performance longevity for white source LED luminaires.

The TE™ 650W white LED source produces 27,000 lumens and a piercing 85,000 lux at 5 meters, and the patent pending Hot-Spot Lens system allows designers to move from a flat field beam to a 6:1 ratio hot-spot beam giving uniform intensity when overlaying beam edges.

“To the best of my knowledge, the ESPRITE™ LED now is the only fixture on the market which offers this type of functionality and doesn’t make the peak beam reflector an after-market decision,” continued John. “From a designer’s perspective, having the opportunity for the ESPRITE™ to come with this device gives us the ability to pick and choose the type of beam field distribution ideal for the lighting design and for any type of utilization and maximum flexibility.”

“During the design phase of all our Robe and Anolis luminaires, we often seek to enlist the input of lighting designers, dealers and distributors worldwide,” explained Josef. “We understand that they are the creative minds who will be applying the technology behind our innovative line of lighting solutions, and we must always try and provide the tools necessary to achieve and exceed their own expectations.”

“Some in the industry who feel there is an adversarial relationship between designers and manufacturers,” concluded John. “Our philosophy at Lightswitch has always been that the relationship is symbiotic as we cannot excel at what we do without manufacturers excelling at what they do!

“One of the things that we enjoy about Robe is the opportunity to be heard early in the product development arc, and in our experience, Robe always asks about our needs. While we understand that not everything we suggest will be included, what is clear is that Robe is very interested in listening to the design community, and it’s very advantageous to have such an open forum to interface with a manufacturer about what we and our clients are needing in the field.”

For more info check the Robe website