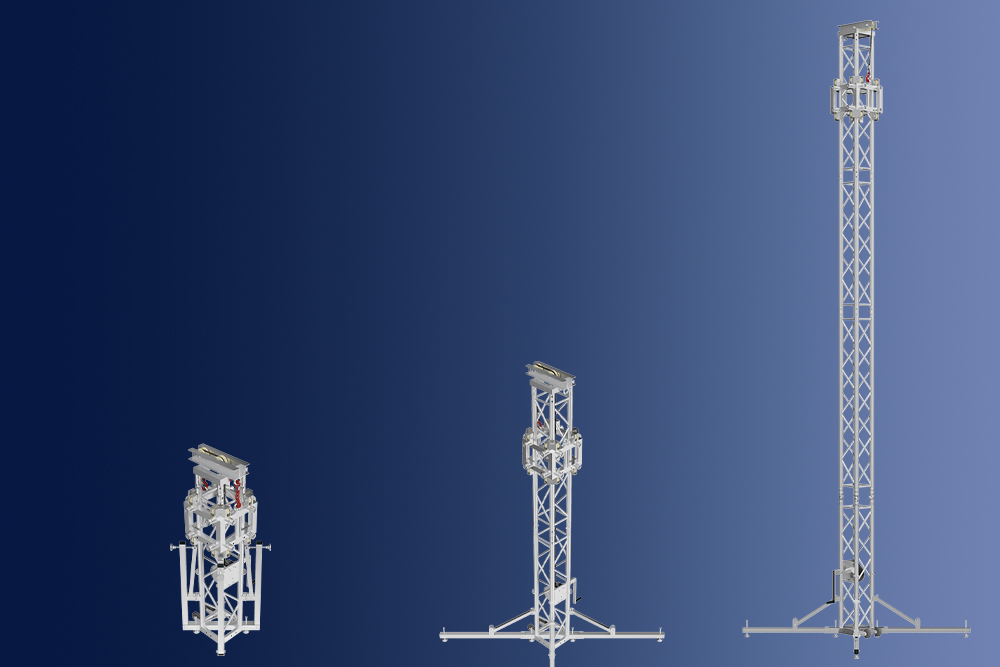

Truss Aluminium Factory, (TAF) based in the Czech Republic, is launching a new all-in-one, light-duty tower system for small roof systems, elevation of truss grids.

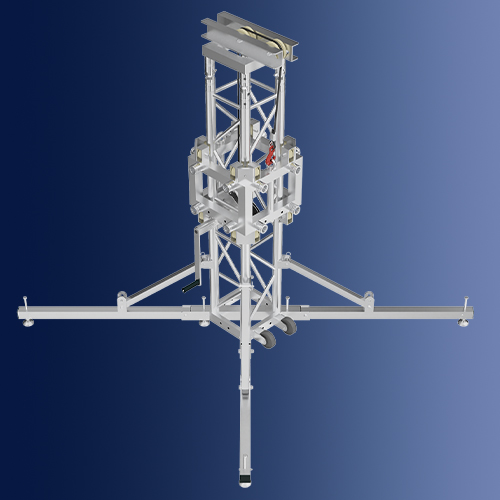

Transport, setup, and use are easy. Just roll out to your location, unfold the outriggers, and attach HT34 truss on top. With HT34’s quicklock connection system, buildup is extremely quick and easy.

Versatility is also ensured, with a welded sleeve block that allows for four-way connection of truss segments to suit a wide range of applications.

Tower 05 features a maximum lifting height of 6.5 m (21.3 ft) and a maximum loading of 500 kg (1,100 lbs).

New and improved features:

– Steel, side-to-side rotating feet for improved leveling on a wide range of surfaces

– Adjustable leg braces for increased stability

– Modified sleeve block allows for smoother travel

– Eight holes (two on each side of sleeve block) allow for convenient mounting of accessories

– Chain hoist connection point on top section

Tower 05 comes with all components for immediate use:

– HT34 truss segments (also compatible with FT34 and TT34 truss series’)

– Aluminum baseplate with outriggers

– Sleeve block

– Top section

– Wheels for trouble-free transport and handling

– Hand winch with steel rope

– Connection kit for truss segments and sleeve block

About Truss Aluminium Factory : TAF is a global manufacturer of aluminium truss, support structures and rigging accessories, with offices in the Czech Republic and the United States. All TAF products are manufactured at its advanced production facilities in the Czech Republic, which feature a full staff of highly experienced welders and a robotic welding machine. A team of specialized engineering and design professionals provide custom and technically demanding solutions for a wide range of projects.

More information on the TAF website and/or contact TAF by email to [email protected]